high speed flexo printing machine Double-station automatic unwinding, independent servo drive system. The printing speed is 450m/min, and the printing effect is the best among flexo printing machines. Suitable for plastic film, PE, PP, BOPP, HDPE, LDPE, paper, non-woven, etc.

Parameter

|

TECHNICAL SPECIFICATIONS |

||||

|

Model |

CHCI4-600F-S |

CHCI4-800F-S |

CHCI4-1000F-S |

CHCI4-1200F-S |

|

Max. Web Width |

650mm |

850mm |

1050mm |

1250mm |

|

Max. Printing Width |

600mm |

800mm |

1000mm |

1200mm |

|

Max. Machine Speed |

500m/min |

|||

|

Max.Printing Speed |

450m/min |

|||

|

Max. Unwind/Rewind Dia. |

Φ800mm/Φ1200mm |

|||

|

Drive Type |

Gearless full servo drive |

|||

|

Photopolymer Plate |

To be specified |

|||

|

Ink |

Water base ink or solvent ink |

|||

|

Printing Length (repeat) |

400mm-800mm |

|||

|

Range Of Substrates |

LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, Breathable Film, |

|||

|

Electrical Supply |

Voltage 380V. 50 HZ.3PH or to be specified |

|||

Video Introduction

The following high speed flexographic printing machine video introduction.

1.Double Station Unwinding

Gearless flexo printing press central drive unwinding is equipped with servo motor. It adopts ultra-light floating roller control and closed-loop control. It has the function of automatically stopping and maintaining tension when the material is cut off.

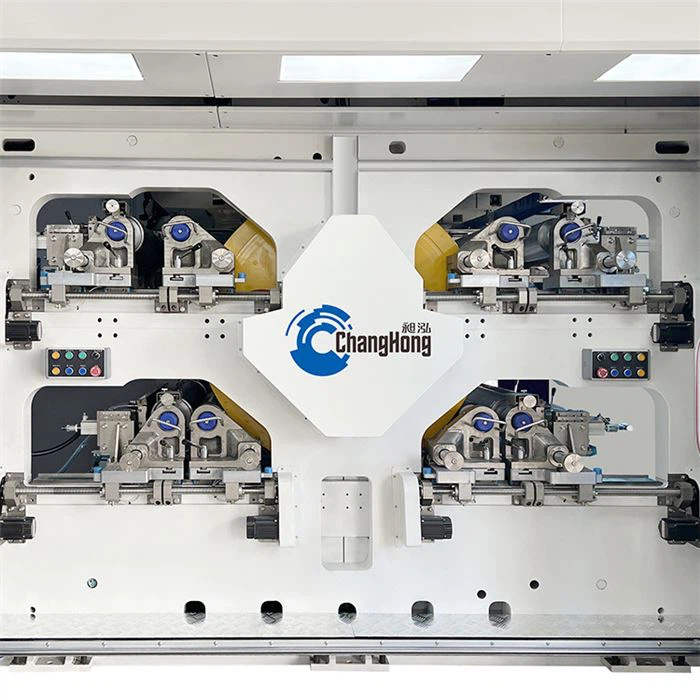

2.Printing Unit

high speed flexo printing machine Printing unit consists of frame, central drum roller ,sleeve printing roller, sleeve anilox roller, chamber doctor blade, ink supply system and an independent servo drive system.

3.Machine Frame

The frame consists of cast iron wall panels and brace. The wall panel is 100mm thick high-strength alloy cast iron (HT250), Resin sand casting, Multi-aging treatment completely eliminates stress, High precision to ensure the rigidity of the frame and the stability of the printing unit.

4.Center impression roller

The central impression roller adopts a double-layer structure, Made of high-quality alloy steel and subjected to precise dynamic balance testing and nickel plating on the surface, ensure that the surface is not corroded.

5.Printing Plate roller

Printing roller adopts the inverted in-line cantilever end locking support structure, and the double line precision roller bearing is closely matched with the air expansion mandrel, which is convenient and quick to replace the sleeve.

Detail Image

Printing Sample

Why choose us?

- Our machines can be easily integrated into existing production lines for seamless workflow.

- Create the best performance is the combination of creating customer value, enhancing company value and realizing the personal value of employees, without performance of the company is like "passive water" can not be sustained, the only way for employees to get a good learning life and career development space is to create performance on the company's platform.

- We keep a close eye on market trends to ensure that our CI Flexo Printing Machines remain competitive.

- Therefore, employees must have a sense of loyalty to the company, a sense of mission, a strong sense of responsibility for their work, the courage to assume responsibility and perform their duties.

- We offer competitive financing options to make our machines accessible to businesses of all sizes.

- We insist on meeting the needs of customers is our pursuit as our business policy, actively contributing to the vast number of new and old customers, and dedicated to providing services to them.

- With our professional expertise and reliable service, we have become a leading supplier and manufacturer in the industry.

- Over the years, our company has been pursuing the tenet of "people-oriented, quality first, and attentive service". We always pay attention to the concerns and needs of customers and provide products and conveniences to customers in many regions of the country and even the world with advanced design concepts, excellent High Speed Flexo Printing Machine quality, and a complete sales system.

- Our CI Flexo Printing Machines are used widely in the printing industry for a variety of applications.

- In recent years, the company has continued to accelerate industrial adjustment and layout, and is committed to the development and production of high-tech products.